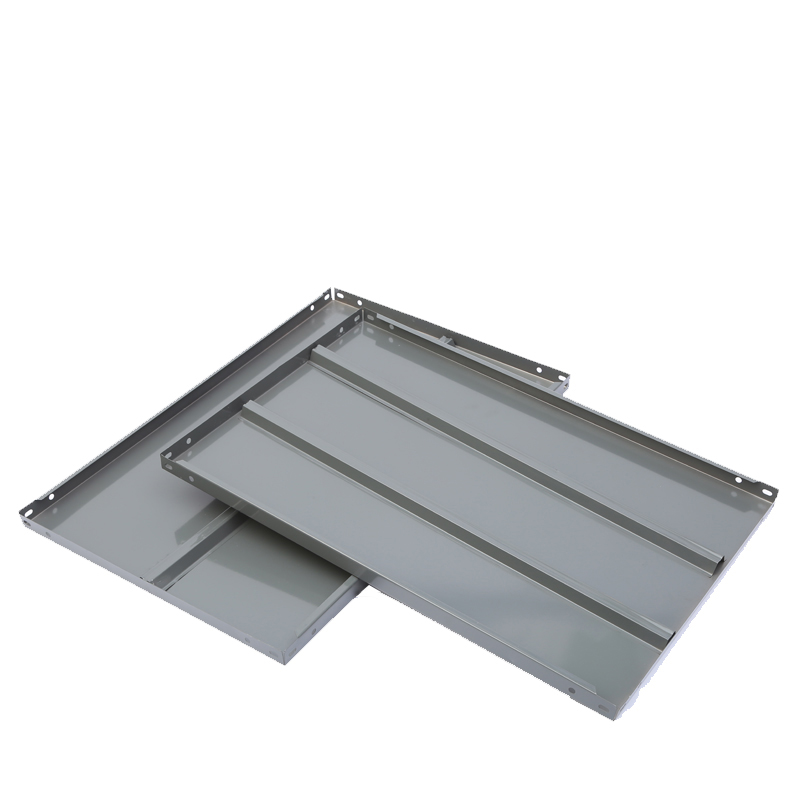

Powder Coated Steel Metal Shelves Rack Shelving Plate

Product Details

Installation steps: First select the raw material carefully and punched. Then formed with high-speed digital control machines. After that, it is the welding of the supports.Finally, the plates will be sprayed by the high temperature electrostatic spraying lines. Then packed in export cartons. 2pcs shelf plate will be faced to faced to ensure stability in transport. Each layers will be use foam bag to protect the shelf plates form scrapping.Then packed in the five-layer corrugated exported cartons. Then will fastened with3 pcs of PP plastic belt.

Application

Suitable for light workplaces such as small parts and accessories.

1.High strength: the angle steel plate can withstand large tension pressure and shear force, and has good resistance to deformation;

2. Convenient installation: The angle steel plate is assembled by bolts, welding, etc., and the operation is simple;

3. Light weight: the density of the angle steel plate is small, which is convenient for handling and installation;

4. Economic energy saving: Compared with other materials, the cost of angle steel plate is relatively low, saving construction costs.

|

Size(mm) |

Supports(pcs) |

Height(mm) |

Thickness(mm) |

|

900*300 |

0 |

30/38 |

0.7-1.2 |

|

900*400 |

1 |

30/38 |

0.7-1.2 |

|

900*450 |

1 |

30/38 |

0.7-1.2 |

|

900*500 |

1 |

30/38 |

0.7-1.2 |

|

900*600 |

2 |

30/38 |

0.7-1.2 |

Product Introduction

Angle racks (also called angle iron racks or steel sheving units) are light-duty storage solutions made of steel slotted angles and iron boards,designed for industrial, commercial, and workshop use. We provide customized and space-efficient storage for different load capacities,tools, equipment and materials.

The requirements of customized products:

Customers need to provide the details as follows

1)Width mm, thickness, length, and trunccstion

2)The shape of hole

3)Order quantity

4)The colors according to international standard color card RAL.

Feature

1) Angle racks are be adjusted and assemlyed freely by your demands.

2) Our products are made of high-quality cold-rolled steel Q235.

3) Angle racks are fixed by nuts and corner plate.

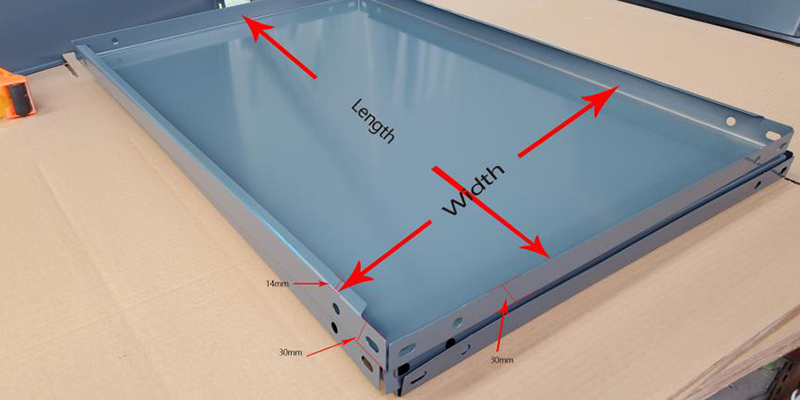

Size

Main parts: upright, layer board, accessory which includeds bolts, nut, corner plates and plastic set.

| Product | Upright:Steel slotted angle |

| Raw Material | Smooth and good strength cold rolled steel coil |

| Type | Equal or unequal (Width on both sides) |

| Technology | Punching, Perforated, Electrostatic/galvanized spraying, Packing |

| Thickness | 0.8-2.5mm |

| Width | 24-60mm |

| Length | 1800-3100mm.Usually 3m, 2.4m, or cut into as customers’ needs |

| Color | White/Grey/Red/Black or refer to RAL card |

| Packing | 10pcs per bundle with PP woven cloth |

| Accessories of each slotted angle | 2 corner plates (optional)

6 sets of blots and nuts (optional) 1rubber foot (optional) |

| Product | Layer board | ||

| Size (mm) | Supports (pcs) | Height (mm) | Thickness (mm) |

| 900*300 | 0 | 30/38 | 0.6-1.0 |

| 900*400 | 1 | 30/38 | 0.6-1.0 |

| 900*450 | 1 | 30/38 | 0.6-1.0 |

| 900*500 | 1 | 30/38 | 0.6-1.0 |

| 900*600 | 2 | 30/38 | 0.6-1.0 |

Accessories for assembling the bolted racks

Special sizes or load capacities can be customized.

Application

Market, store, storeroom, garage, study, office, showroom and warehouse etc.

Production process

1) Punching the holes:

https://youtu.be/xN5GJvy2eLc

2) Forming:

3) Cutting:

4) Power coating:

5) Package

Package

1)10/20pcs packed by PP woven cloth.

2)10pcs packed by export mail cartons.

About us

Linyi Zhiding Import And Export Co.,Ltd, with the factory of Linyi City Lanshan District Angle Hardware Co.Ltd, majored in producing the steel slotted angle, boltless shelves, warehouse rack and supermarket shelf, is a comprehensive enterprise of designing, manufacturing, and trading.

The company is equipped with advanced production lines as cold-rolled forming line, automatic and continuous steel strip punching line and electrostatic powder-spraying coating line. Meanwhile, we have a professional team of manufacturing, sales, shipping and after -sales service. The products are widely exported to South-East Asia, Middle East, South America, South Korea, Japan and so on.

Advantage

1) Factory directly selling without middlemen.

2) We can supply serivice that make your container full. If your containers have some space left, we can supply you with other goods. Or we can load the goods which you buy from other factory.

3) We have more 20 years experience of professional production and exporting. You can belive our professionalism. We are familiar with our rack industry and our products, alse we can handle with various difficult problems.

Loading

1) Bulk goods can be packed into pallets and deliveryed to Yiwu warehouse, Guangzhou warehouse or other exporting warehouse.

2) Full container goods is usually loaded into 20GP and the weight should not exceed 28000kgs.

3) Bulk goods can also be loaded with other light goods to fullfill the 40HQ.The steel slotted angle will be put at the bottom of the container and light goods put on the angles.This is the best way to make full use of the container. In this way , the weight of the goods will be not exceed 28000kgs while the container is full.

Product Introduction

Angle racks (also called angle iron racks or steel sheving units) are light-duty storage solutions made of steel slotted angles and iron boards,designed for industrial, commercial, and workshop use. We provide customized and space-efficient storage for different load capacities,tools, equipment and materials.

The requirements of customized products:

Customers need to provide the details as follows

1)Width mm, thickness, length, and trunccstion

2)The shape of hole

3)Order quantity

4)The colors according to international standard color card RAL.

Feature

1) Angle racks are be adjusted and assemlyed freely by your demands.

2) Our products are made of high-quality cold-rolled steel Q235.

3) Angle racks are fixed by nuts and corner plate.

Size

Main parts: upright, layer board, accessory which includeds bolts, nut, corner plates and plastic set.

| Product | Upright:Steel slotted angle |

| Raw Material | Smooth and good strength cold rolled steel coil |

| Type | Equal or unequal (Width on both sides) |

| Technology | Punching, Perforated, Electrostatic/galvanized spraying, Packing |

| Thickness | 0.8-2.5mm |

| Width | 24-60mm |

| Length | 1800-3100mm.Usually 3m, 2.4m, or cut into as customers’ needs |

| Color | White/Grey/Red/Black or refer to RAL card |

| Packing | 10pcs per bundle with PP woven cloth |

| Accessories of each slotted angle | 2 corner plates (optional)

6 sets of blots and nuts (optional) 1rubber foot (optional) |

| Product | Layer board | ||

| Size (mm) | Supports (pcs) | Height (mm) | Thickness (mm) |

| 900*300 | 0 | 30/38 | 0.6-1.0 |

| 900*400 | 1 | 30/38 | 0.6-1.0 |

| 900*450 | 1 | 30/38 | 0.6-1.0 |

| 900*500 | 1 | 30/38 | 0.6-1.0 |

| 900*600 | 2 | 30/38 | 0.6-1.0 |

Accessories for assembling the bolted racks

Special sizes or load capacities can be customized.

Application

Market, store, storeroom, garage, study, office, showroom and warehouse etc.

Production process

1) Punching the holes:

https://youtu.be/xN5GJvy2eLc

2) Forming:

3) Cutting:

4) Power coating:

5) Package

Package

1)10/20pcs packed by PP woven cloth.

2)10pcs packed by export mail cartons.

About us

Linyi Zhiding Import And Export Co.,Ltd, with the factory of Linyi City Lanshan District Angle Hardware Co.Ltd, majored in producing the steel slotted angle, boltless shelves, warehouse rack and supermarket shelf, is a comprehensive enterprise of designing, manufacturing, and trading.

The company is equipped with advanced production lines as cold-rolled forming line, automatic and continuous steel strip punching line and electrostatic powder-spraying coating line. Meanwhile, we have a professional team of manufacturing, sales, shipping and after -sales service. The products are widely exported to South-East Asia, Middle East, South America, South Korea, Japan and so on.

Advantage

1) Factory directly selling without middlemen.

2) We can supply serivice that make your container full. If your containers have some space left, we can supply you with other goods. Or we can load the goods which you buy from other factory.

3) We have more 20 years experience of professional production and exporting. You can belive our professionalism. We are familiar with our rack industry and our products, alse we can handle with various difficult problems.

Loading

1) Bulk goods can be packed into pallets and deliveryed to Yiwu warehouse, Guangzhou warehouse or other exporting warehouse.

2) Full container goods is usually loaded into 20GP and the weight should not exceed 28000kgs.

3) Bulk goods can also be loaded with other light goods to fullfill the 40HQ.The steel slotted angle will be put at the bottom of the container and light goods put on the angles.This is the best way to make full use of the container. In this way , the weight of the goods will be not exceed 28000kgs while the container is full.